A meeting amongst the universal greats goes well as James helps them integrate their technology

Below are four of many pioneers of the electrical world, see if you can guess who they are?

10 Facts About Distribution Boards!

- Board Hight must be set 1.2m from Ground

Did you know a board should be mounted at approximately 1.2m high, This is not only for easy access for most but also for people in wheelchairs as they can access the consumer unit in case of a fault.

- Max 1mm Hole on top & Front of CU/DB

Did you know we are not allowed no more than a 1mm hole in diameter at the top and front of a consumer unit/distribution board, as this doesn’t meet the ingress protection requirements (IP4X).

- Gaps Between RCBO's

Did you know it is best practice to space out your RCBOs as they can build up a large thermal signature, and this will help them dispute the heat? If RCBOs get hot this can cause all sorts of issues such as not operating correctly.

- RCD Maximum Leakage

30% of a 30mA RCD gives a maximum allowable amount of 9mA leakage for normal operation. This requirement may be hard to meet if you have several circuits protected by one RCD and you don’t know what equipment will be used in the installation.

- Isolating Line Conductors

Three-phase distribution boards generally have 3-pole switch disconnectors which isolate all line conductors but not the neutral. This is fine for TN-C-S and TN-S systems providing protective bonding is installed and the neutral conductor is reliably connected to Earth by a low resistance (see Regulation 461.2).

- SPD & MET Protection

The minimum protective conductor size needed for connection between SPD and MET is 6mm2 copper or equivalent. As for Type 2 SPDs, it is 16mm2 for Type 1 SPDs The total length of conductors between connection points of the SPD assembly should not exceed 0.5 m (preferably) and in no case exceed 1.0 m.

- Torquing Your Terminals

Every consumer unit has torque settings. If the screws are not correctly tightened this can cause under tightening or over tightening. Which can lead to many issues such as loose connections and damage to the equipment.

- RCD Maintenance

RCDs should be checked at a maximum interval of every 6 months by pressing the test button. This then lubricates the mechanics of the RCD to ensure mechanical operation. This used to be a quarterly test but in recent years has changed.

- Correct Screwdriver Bit

Many screws in consumer units are not what most people believe to be PZ2 but SL/PZ2 so always make sure to use the correct screwdriver end for the job. ALWAYS refer to manufacturer instructions.

- KA Rating?

What is the KA rating on a Protective device? It is the maximum the protective device can handle to safely isolate under fault conditions. If the KA goes above the maximum, the protective device may not operate safely and correctly.

We have partnered up with one of the most prestigious tool brands within the industry... Metabo.

Unleashing a quiet revolution, these 18v batteries sneakily turn your work into a masterpiece, leaving you wondering if your tools have been hitting the gym. It's the not-so-secret sauce to making your job shockingly good. Don't be surprised if your drill starts flexing its bits.

Spend £300.00 Inc VAT on Metabo 18V cordless and redeem a FREE 18V LiHD 5.5Ah battery pack.

Promotion runs from 1st January 2024 - 31st March 2024Check us out!

RCBO Heat Effecting Performance

The performance of Residual Current Circuit Breakers with Overcurrent Protection (RCBOs) can be influenced when installed next to each other within an electrical panel or enclosure. Several factors need consideration to ensure their safe and dependable operation, The various concerns are the following:

Heat Dissipation

The tight placement of RCBOs restricts airflow and reduces heat dissipation which increases operating temperatures, which can compromise performance, reduce longevity and potentially make the installation unsafe. Always refer to manufacturers' instructions to see what they recommend. It is best practice to space out your RCBOs where possible and this will help with heat dissipation from other RCBOs.

Electromagnetic Interference (EMI)

When RCBOs are closely situated, electromagnetic interference between devices may impact sensitivity to fault currents and trip characteristics.

Temperature Rise

You may ask where the heat stems from. This is caused by the coil inside the RCBO which gets hot under operation. So when placed in between another RCBO on either side it is a lot harder for the heat to dissipate.

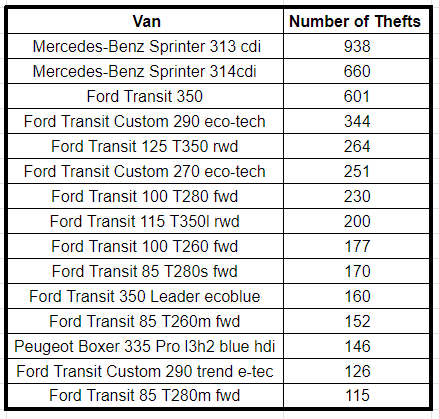

The most STOLEN van in the UK has been confirmed it's the Mercedes-benz Sprinter 313 CDI with a total of 938 thefts followed by the Sprinter 314 CDI at 660 and the Ford Transit 350 ranked third, with 601 reported stolen according to the DVLA.

Last year, van thefts surged to 12,950 in the UK, up 18% from 2022. Despite being fewer than car thefts, which rose 5% to 64,087, drivers remain vulnerable to vehicle theft.

Source - Electrical Times

If you are interested in becoming a sponsor of the newsletter or want to be featured like Mark above please don't hesitate to reach out. Link to contact us below

Contact us here!The material and information contained in this newsletter is for informational purpose only, you should not rely upon the material or information on this newsletter, all readers must make their own judgment and seek professional advice when making decisions based on the context of the newsletter