In today's newsletter, we're exploring into the essentials of isolation and switching, sharing some of the biggest pet peeves electricians face on the job, and decoding the on-site slang you hear every day (and still might be pretending to understand).

Isolation and switching are key safety steps in any electrical job. Whether it's a home, business, or industrial site, ensuring circuits are safely shut off prevents shocks, restarts, and damage. In this issue, we break down what you need to know.

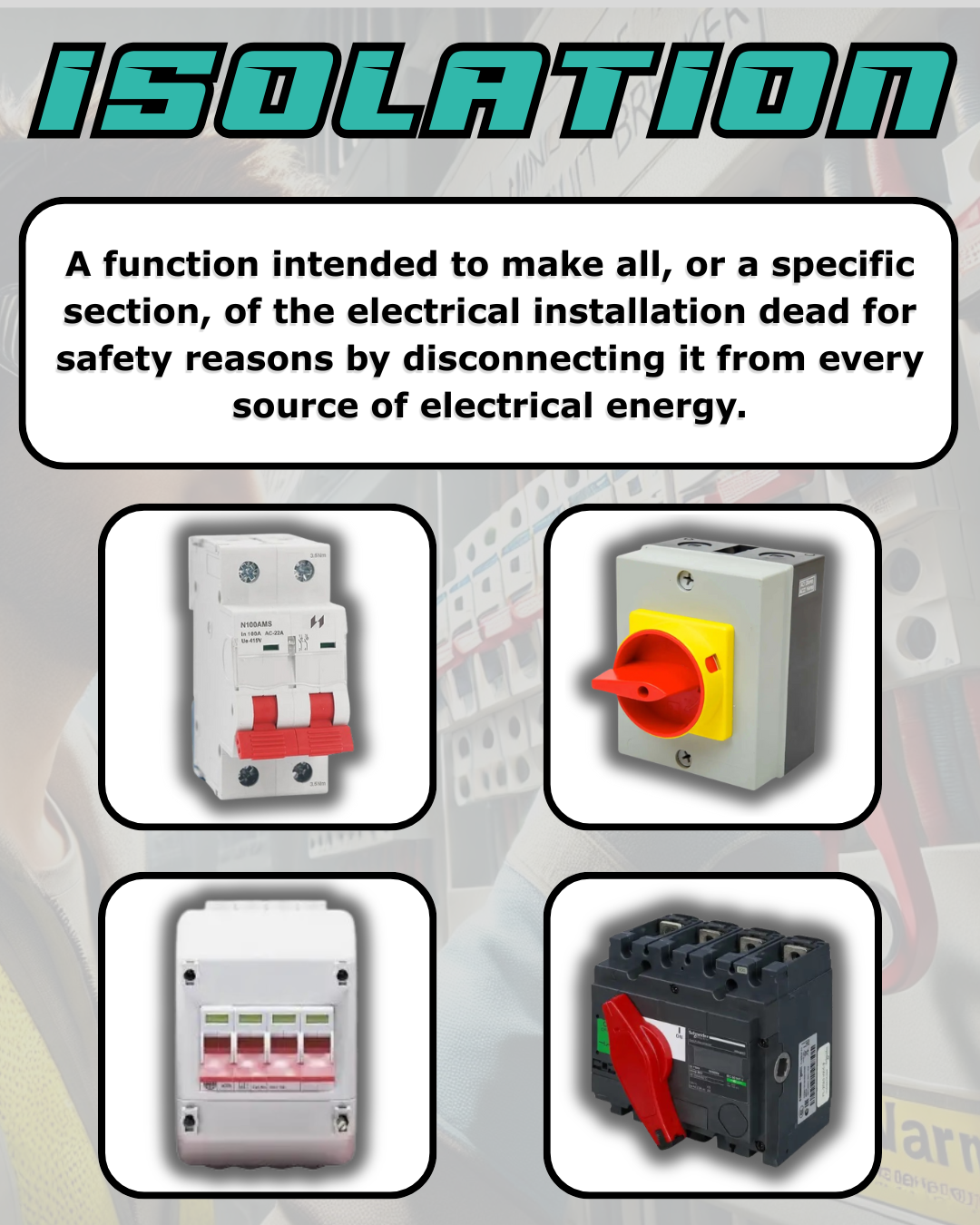

Isolation

Isolation involves completely disconnecting electrical equipment or circuits from their power source to ensure they are dead and safe to work on. This prevents accidental re-energisation and eliminates the risk of electric shock.

An isolator must be capable of being secured in the OFF position, often using a padlock or lock-off device, so that no one can unintentionally restore power while you or someone else is working on it. Unlike functional switching, isolation is not used for regular operation it is strictly for safety during maintenance and repair.

For example, before servicing an industrial motor, an electrician would isolate the supply using a dedicated isolator switch. This ensures that even if someone accidentally presses the start button, the motor cannot restart, preventing potential injury.

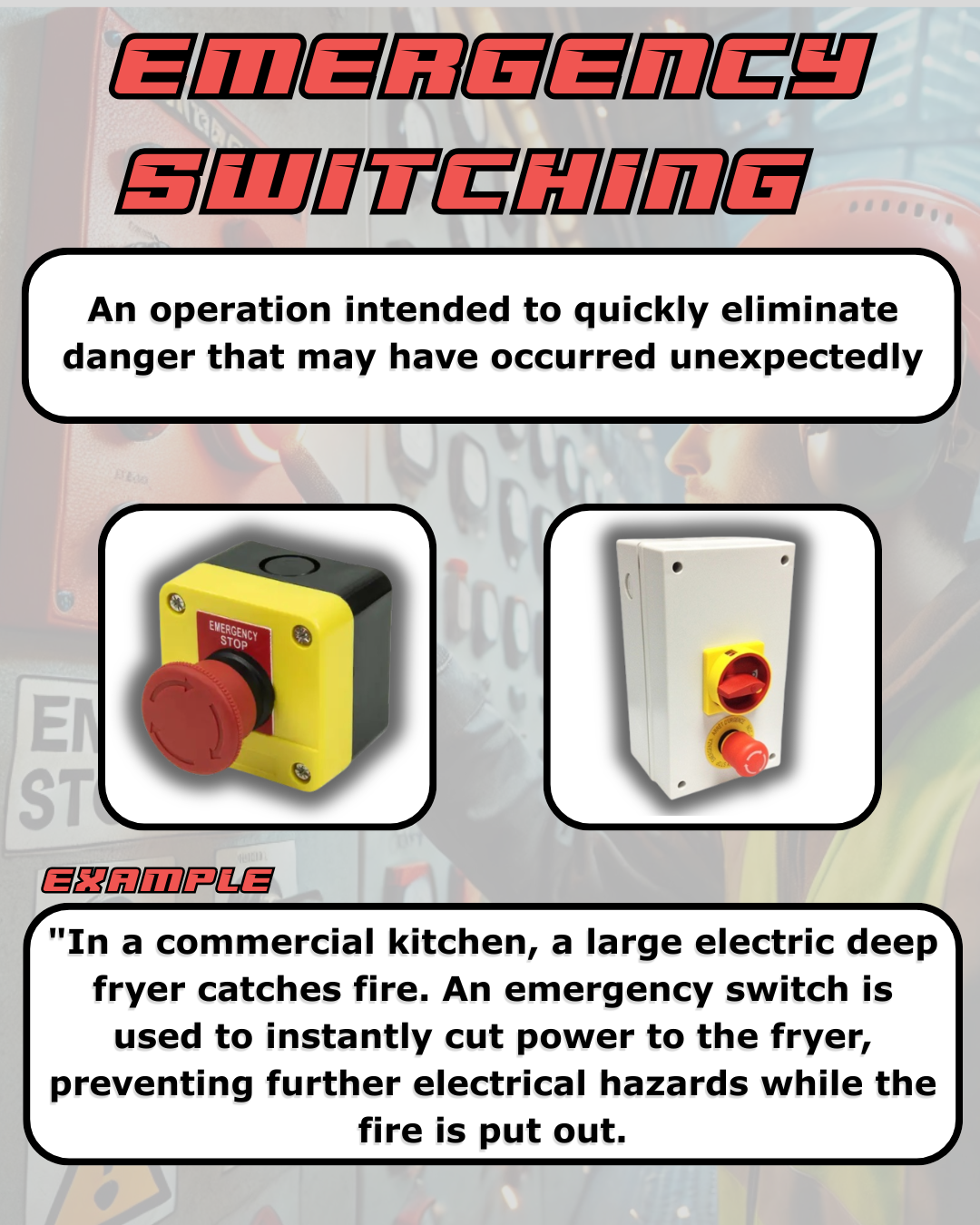

Emergency Switching & Emergency Stopping

Both emergency switching & emergency stopping are critical safety functions, but they serve different purposes in electrical systems.

- Emergency Switching is used to quickly cut off power to eliminate danger. It is typically used for electrical hazards, such as a person receiving an electric shock or a fire starting in electrical equipment. For example... A large isolator switch outside a machine room instantly disconnects power in case of an electrical fault.

- Emergency Stopping is used to halt the operation of a machine while keeping power supplied to safety-critical components. It is primarily for mechanical hazards rather than electrical ones. Emergency stop buttons are commonly seen on machinery where stopping moving parts can prevent injury without fully cutting power.

- Pressing it stops the belt instantly to prevent someone's hand from being caught, but power remains on for control systems.

The key difference is that emergency switching removes electrical hazards by disconnecting power, while emergency stopping prevents mechanical danger by stopping movement without full power isolation.

Switching Off For Mechanical Maintenance

This method stops machinery from running during maintenance without shutting off the entire electrical supply. The control circuit or supply side stays live, but the load side is disconnected-making the machine safe to work on. Unlike full isolation, which cuts all live conductors, this approach keeps the wider system powered while ensuring the equipment being serviced is dead.

For example, when servicing an air conditioning unit, the local isolator cuts power to the unit, allowing safe access to internal parts, while the supply cable before the isolator remains live. To avoid accidental reconnection, the switch must be clearly labelled and locked in the off position-often with a lockable switch or physical indicator.

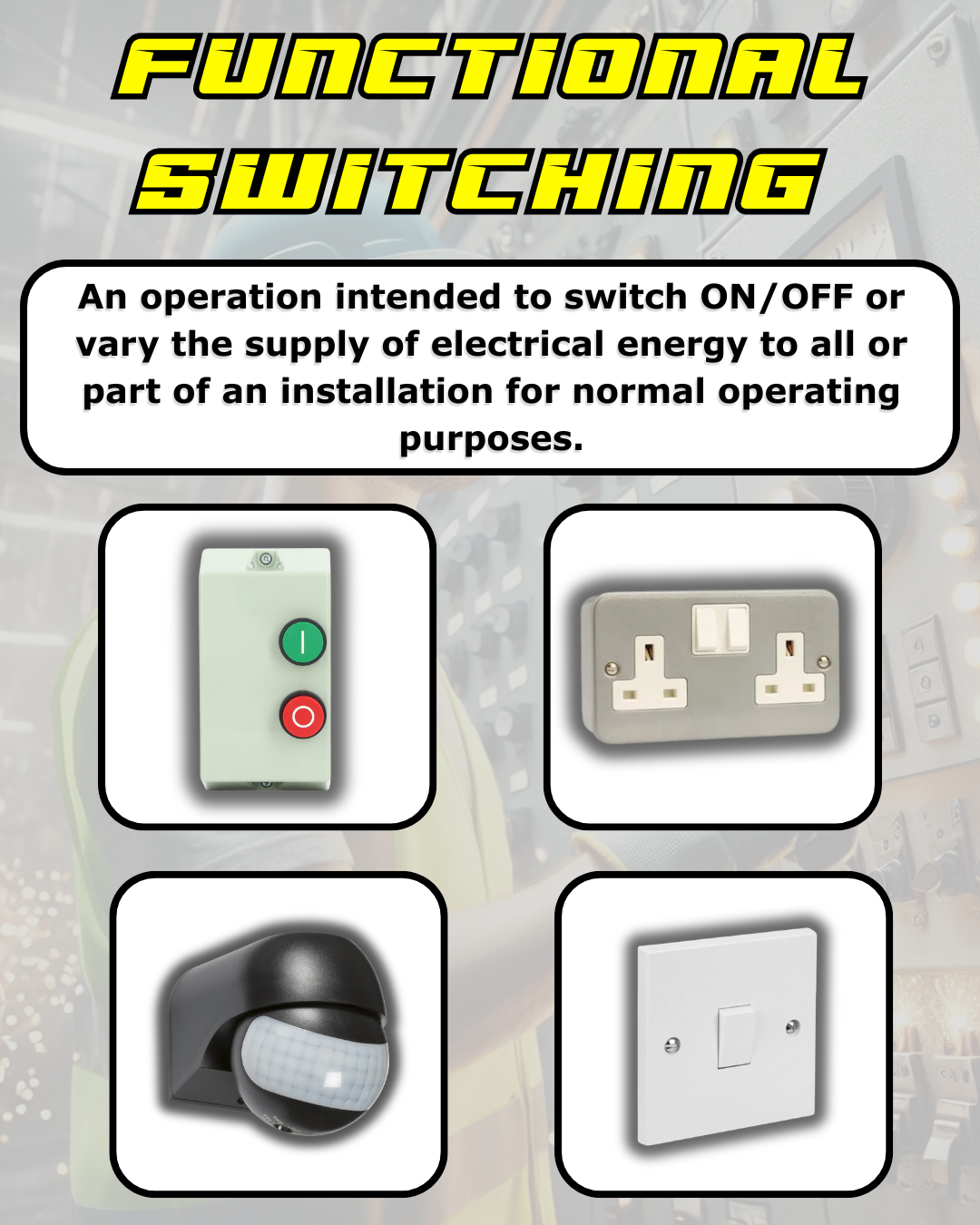

Functional Switching

Functional switching is the everyday control of electrical equipment-turning it on or off during normal use. It's not about safety, unlike isolation or emergency switching.

These switches must be easy to reach and built for frequent use. Common examples include light switches, motion sensors (PIRs), and start/stop buttons on machines.

In a warehouse, for example, a key-operated switch might control high-level lighting, allowing only authorised staff to use it. While functional switches manage power flow, they don't isolate circuits and should never be used for safety during maintenance.

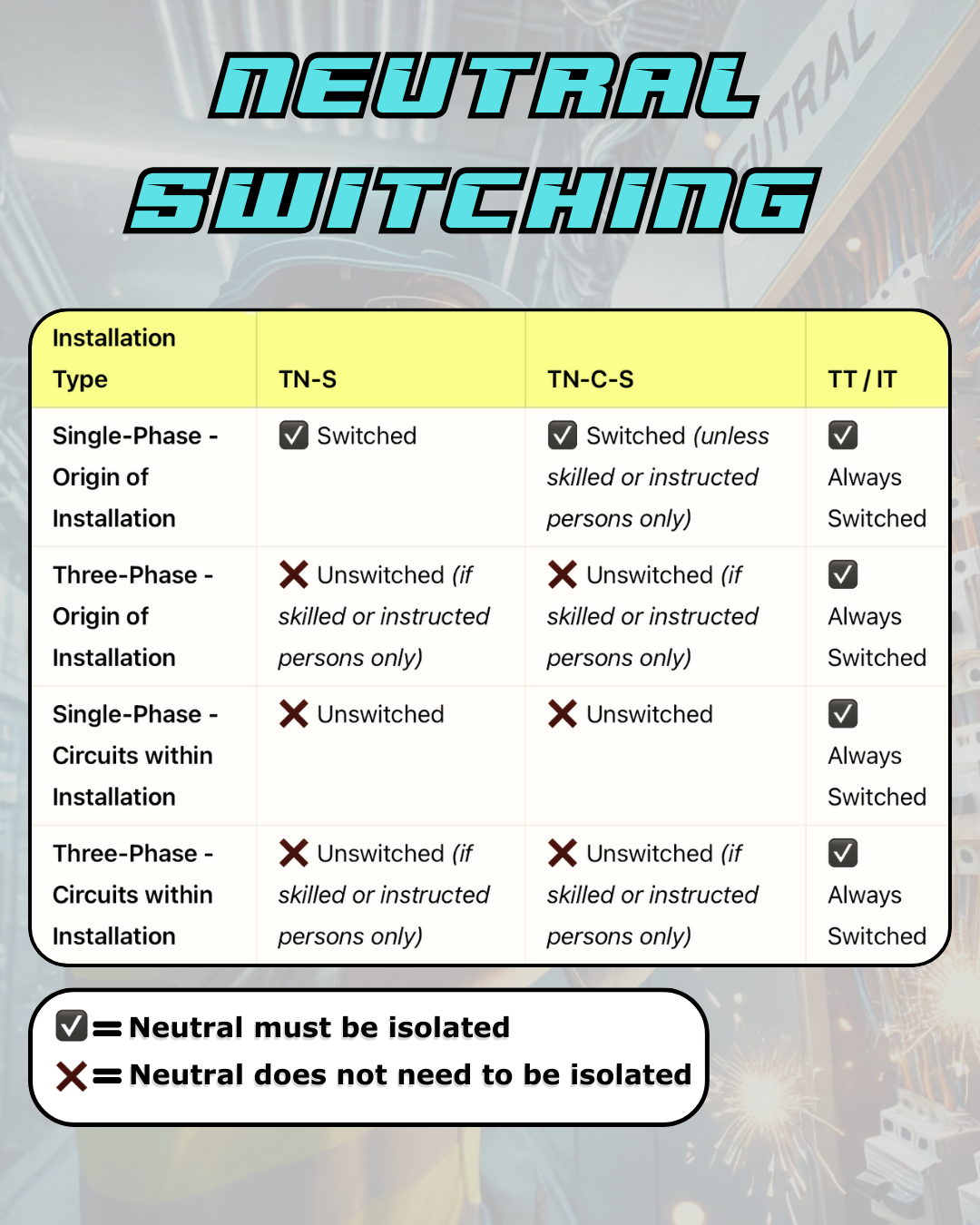

Neutral Switching

In electrical installations, deciding whether to switch the neutral conductor depends on the earthing system, installation type, and regulations.

For example, in TT and IT systems, the neutral must always be isolated for safety. In TN-S and TN-C-S systems, it's usually left connected to maintain a stable return path. Incorrectly switching the neutral can cause floating voltages, instability, or loss of PME earthing-posing serious safety risks.

This decision is critical during the design phase, especially for main isolators, distribution boards, and backup power supplies. Electricians should always consult the latest IET Wiring Regulations (BS 7671) and manufacturer guidance to ensure safe and compliant installations.

Here are 5 quick-fire questions to put your trade knowledge to the test

- What is the minimum height for a socket outlet in a new-build domestic property (according to Part M of Building Regs)?

- 200mm

- 250mm

- 450mm

- 600mm

- Who invented the first practical incandescent light bulb?

- Nikola Tesla

- Alessandro Volta

- Thomas Edison

- Michael Faraday

- Which of the following cables is the most suitable for burial underground (with proper protection)?

- Twin & Earth

- SY Cable

- Flex Cable

- SWA Cable

- What does IP44 indicate?

- Fully waterproof

- No dust or water ingress

- Protection from solid objects over 1mm & splashing water

- Only indoor use

- What is the worst thing a customer can say to you?

- "It'll only take 5 minutes"

- "My uncle's a bit of a handyman, he already had a go at it."

- "While you're here..."

- All of the above

If you've ever wrestled with getting a clamp meter into a tight electrical cabinet, you're not alone. Some jobs just aren't made for rigid tools.

That's where the MA400D-250 DigiFLEX Ammeter comes in. A flexible sensor, compact display, and magnetic mount mean you can measure currents up to 400A in 600V CAT IV locations.

✔️ Wrap-around sensor for easy setup

✔️ 4,000-count digital display - no guesswork

✔️ Magnetic Multifix mount - stick it, set it, forget it

No more fumbling, no more frustration. Just accurate, hassle-free readings.

On-site, you'll often hear electricians using certain phrases, but what do they mean?

Cable Pulling -

When installing cables, it's common for multiple electricians to work together, especially when pulling long lengths through buildings or tight, awkward spaces. This helps ensure the cable is fed through smoothly and safely, without causing any damage along the way.

Chasing -

Make a channel in a surface, normally brick or plaster so a cable can be routed and plastered over.

De-energized -

A piece of equipment or part of an electrical installation that has been switched off or isolated.

First Fix -

The first two stages of installing a wiring system. This stage will involve preparing & installing containment for cable, pulling cables into the containment and fixing or screwing boxes for light switches, socket outlets etc to the walls.

📷 - Mazhar Iqbal

📷 - Mazhar Iqbal

Fixing -

Securing refers to the act of fixing a piece of equipment to a surface-like attaching a conduit saddle to a wall or ceiling using screws and wall plugs. It ensures everything stays firmly in place and meets installation standards.

Glanding -

The process of connecting a cable, such as SWA (Steel Wire Armoured) to an accessory. Glands are specifically designed to match the type, size, and shape of a particular cable, meaning they're not usually interchangeable.

Reaming -

After cutting a hole or a length of conduit, any sharp burrs, metal shavings, or leftover debris must be removed. This clean-up process is known as reaming, and it's done using a tool called a reamer.

Second Fix -

The second of two stages of installing a wiring system. This stage will involve terminating electrical equipment and accessories.

Stripping Out -

The removal of redundant electrical installations.

- ✅ C) 450mm

- ✅ C) Thomas Edison

- ✅ D) SWA Cable

- ✅ C) Protection from solid objects over 1mm & splashing water

- ✅ D) All of the above...

We surveyed a number of electricians to find out what really grinds their gears on the job. Here's what they had to say...

- Unlabelled circuits

- Customers asking, "Is it dangerous?" mid-fix

- Broken screw terminals on the last outlet of the day

- Unlevel sockets and switches

- Plasterers covering back boxes

- Short cable runs with no slack

- Concrete-filled conduit

- Customers who hover over you

- DIY wiring disasters

- Losing screws mid-install

If you are interested in becoming a sponsor of the newsletter or want to be featured like Mark above please don't hesitate to reach out. Link to contact us below

Contact us here!The material and information contained in this newsletter is for informational purpose only, you should not rely upon the material or information on this newsletter, all readers must make their own judgment and seek professional advice when making decisions based on the context of the newsletter