Now a base is set-up on earth, Jimbo is sending signals to outer space. I wonder who might receive them...

One thing we hope is that you, the reader, have a passion for the electrical industry, otherwise you wouldn't be reading this. We hope that each week every single reader enjoys the content we share.

Celebrating 1 Year of Watts Up in August we are doing our biggest giveaway to date of electrical tools to one of our lucky subscribers.

All you have to do to be in with a chance of winning:

- Subscribe... which you are, otherwise you wouldn't see this

- Open and read 1 of the following volumes - May, June, July, August volumes

Winner will be announced on August 1st 2024, within the newsletter

More details on what we are giving away coming soon!

What is Premature Collapse?

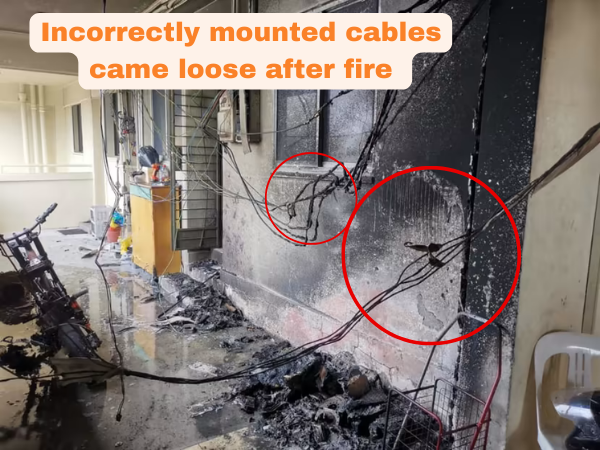

Premature collapse is the unexpected failure of a structural support that maintains electrical cables. A collapse of the support can occur due to various factors, such as:

- Fire

- Mechanical Stress

- Environmental Conditions

In the event of a collapse, the electrical cables can hinder firefighting efforts, causing disruptions to critical services and even endangering lives. An example is from 6th April 2010, when a fire started in the Shirley Towers, Southampton UK. While the fire was being tackled, two firefighters became entangled in cables that had fallen from melted plastic trunking. As a result, the firefighters sadly lost their lives, and this could of been avoided...

BS7671 Requirements for Premature Collapse

Regulation 521.10.202 of BS 7671:2018 states "Wiring systems shall be supported such that they will not be liable to premature collapse in the event of a fire."

This is very self explanatory from a reader's perspective but how do you actually apply this?

How & Where To Support Cables To Prevent Premature Collapse?

Referencing the regulation, it has 4 notes which explains the how and where details in more depth.

- Note 1 - Wiring systems hanging across access or egress routes may hinder evacuation and firefighting activities.

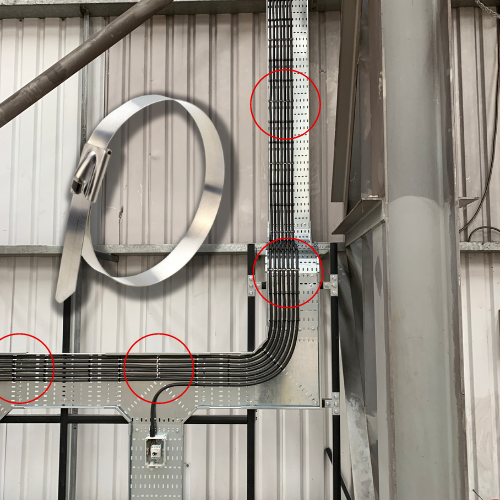

- Note 2 - Cables installed in or on steel cable containment systems are deemed to meet the requirements of this regulation.

- Note 3 - This regulation precludes, for example the use of non-metallic cable clips or cable ties as the sole means of support where cables are clipped to exposed surfaces or suspended under cable tray and the use of non-metallic cable trunking as the sole means of support of the cables therein.

- Note 4 - Suitably spaced steel or copper clips, saddles or ties are examples that will meet requirements of this regulation.

Can Plastic Plugs Be Used?

Common and valid question if you are fitting metal fixings, in the NAPIT On-Site Solutions it states the following:

"It is often asked if plastic plugs are an acceptable method of fixing supports with regard to premature collapse. Plastic plugs have been used to fix wiring systems for many years, including fire alarm systems used where there is a particular risk of fire. Whilst cables such as mineral insulated are specified because of their properties to withstand heat. Historically plastic plugs have not been a concern. The intent of this Regulation is to prevent the use of non-metallic clips, ties and wiring systems as the sole means of support. Therefore, plastic plugs are acceptable providing they have been correctly selected and installed."

Products To Clip/Fix Cables - (Non Containment)

Metal Cable Ties

These can be used on cable trays, baskets or where your fixings are adjustable.

Metal Clips

These are perfect if you are clipping a cable directly to the surface of the wall.

Trunking Clips

These are great if you are installing plastic trunking as they will still hold the cables even in the event of a fire.

Cable Clipping & Distances

Twin & Earth and SWA cable - Referencing directly out of the IET On-Site Guide:

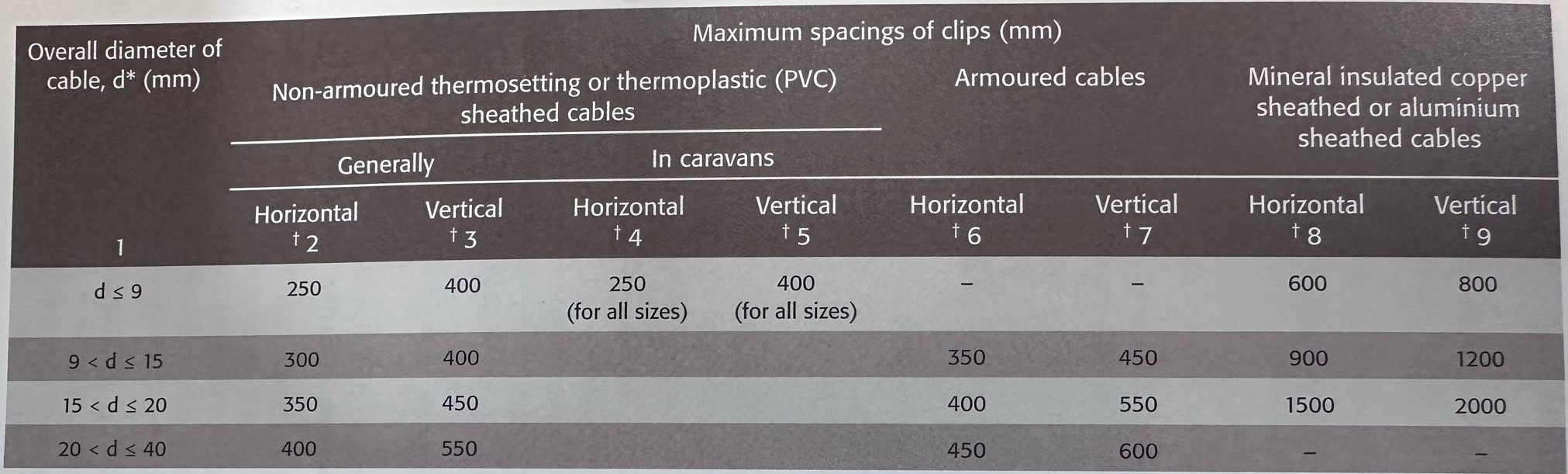

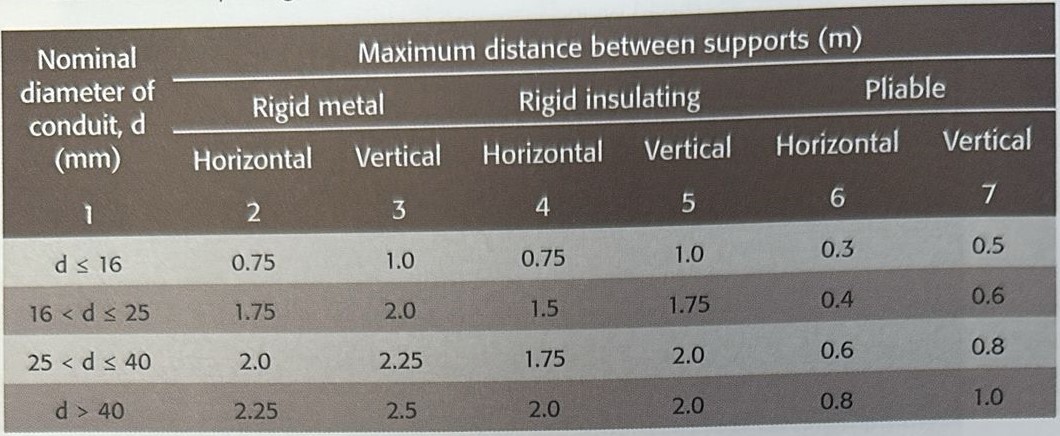

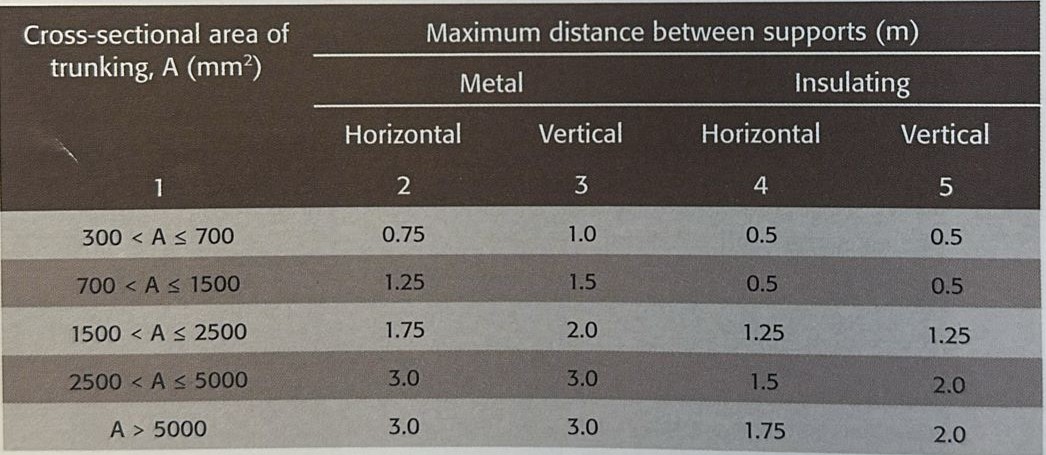

D1 - Spacing Of Supports For Cables In Accessible Positions

D3 - Spacings Of Supports For Conduits

D4 - Spacings Of Supports For Cable Trunking

As an additional note, it highly suggested that fire resistant fixings should be used for fire resistant cables.

For more information please check out this excellent guide by BEAME.

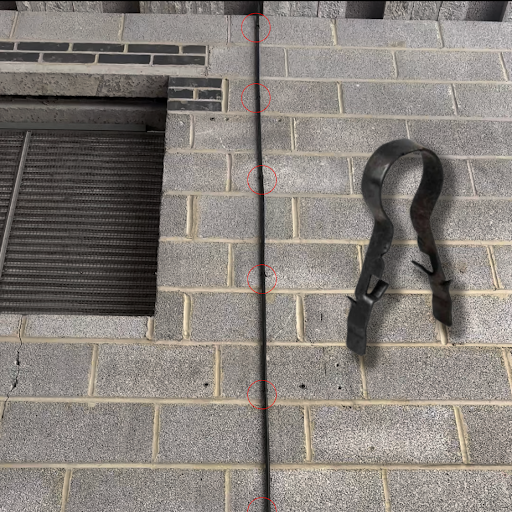

Cleats, saddle clips, p-clips, conduit saddles & even all round band are ways to fix your cable to a surface, but they all have their issues. They can be slow to install and just a overall pain.

Imagine a solution that is x3 faster, safer and simpler.

Introducing LINIAN Clips which only requires you to drill a hole, slide the clip over the cable or conduit, and push or tap it in. No bulky tray of fixings, no plugs, no screws, no washers, just a bag of LINIAN Clips.

To top it off, they are fire-rated so they'll hold cables securely in case of fire which comply with 18th Edition Wiring Regulations. As you read previously, this could be a literal lifesaver.

LINIAN Clips

LINIAN Clips

Surge In Demand For Three-Phase Supply

Many of the homes across the world, especially the UK, have 70's/80's electrical wiring. In previous decades, the single-phase supply was adequate. Today, however, our household electricity needs grow year-on-year. Coming into force in 2025, the Future Homes Standard is a government initiative requiring new homes to reduce carbon emissions by 75%. Notably, it omits electricity supply. Installing single-phase supplies in new homes has been the norm since before WWII back when lights were the main household load. Now, our homes do more and will do even more in the future such as EV Charging, Heat Pumps, Hot Tubs, Showers, Battery Charging System and much more

Solar Power Revolutionized 2.0

Recently researchers have developed an organic photovoltaic film that is both waterproof and flexible, allowing a solar cell to be put onto clothes and still function correctly after being rained on or even washed, which is a gamechanger for the industry to reduce weight and more importantly how we can fix them to buildings. (Source - RIKEN)

Growing Apprenticeship Opportunities

Rishi Sunak has announced from the 1st April onwards that the UK are to be implementing a regulation change where small to medium-sized electrical businesses will save on apprentice hire costs. This is only applicable to people aged 21 and under, on average we see a saving of approximately £2,000 over a 4-year apprenticeship.

UK EV Charging Grant

Under the new rulings, EV drivers who live in cities & more populated areas and do not have access to their garage will be able to claim up to 75% off the cost to buy and install a charging socket, up to a maximum of £350. Check out the local gov website for more as this could be a great marketing opportunity.

The variety of cables available to us are endless, they all have different purposes for different situations. Below are some of the more common cables used in an industrial/commercial setting.

LSF (Low Smoke and Fumes)/ LSHF (Low Smoke Halogen Free) Cable

Made from a PVC compound that has been altered to decrease the amount of gas and smoke that is produced when burning, compared to traditional PVC cables. Typically used in applications where a risk of fire may be present. Credit FS Cables for the photo and check out the video for real time view on how the cable burns.

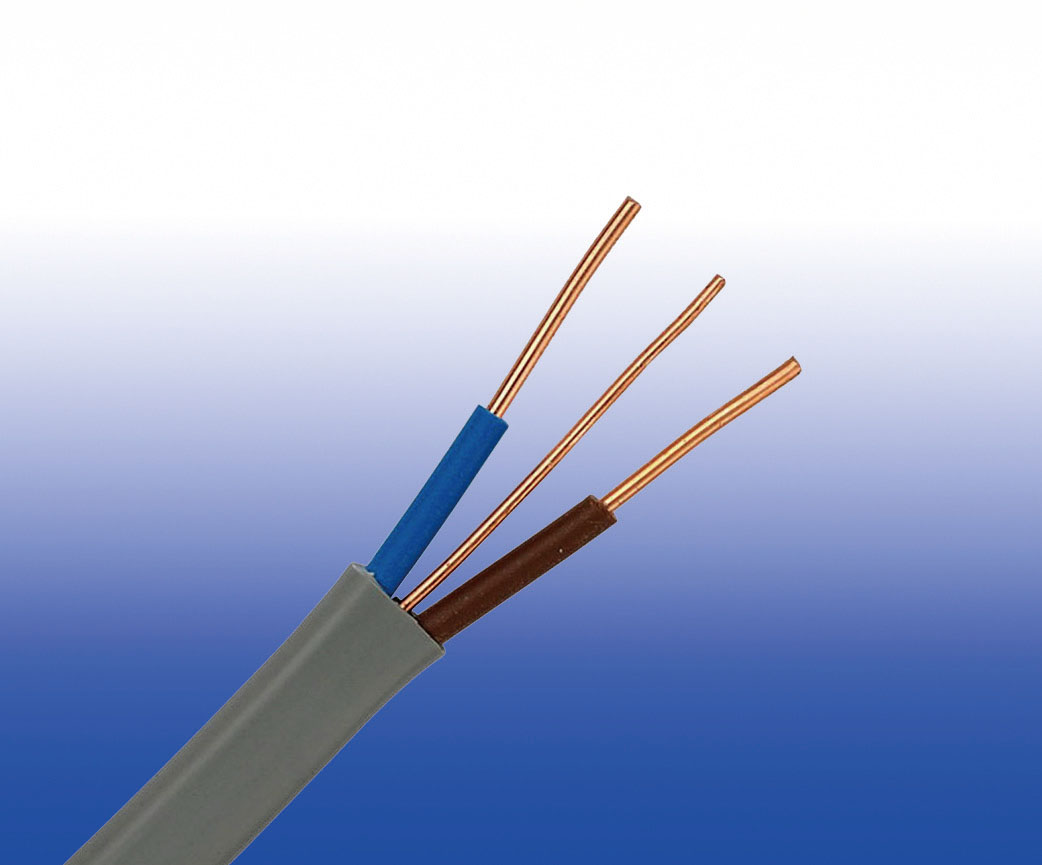

Twin & Earth Cable

The most popular cable in the domestic industry and used in the majority of applications such as wiring installations in lighting circuits, power outlets, and other electrical connections. Twin and earth cable comes in various sizes and configurations to accommodate different electrical loads and installation requirements.

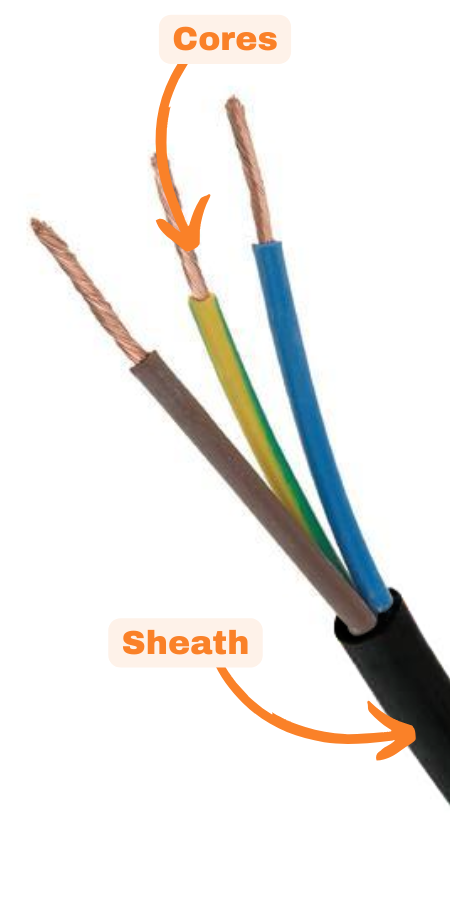

Armoured Cable

This type of cable is specifically designed for use in harsh environments where extra protection is needed. The key feature of armoured cable is it's layer of steel wire that encases the insulated conductors within the cable which provides mechanical protection against physical damage, moisture, chemicals, and other environmental hazards.

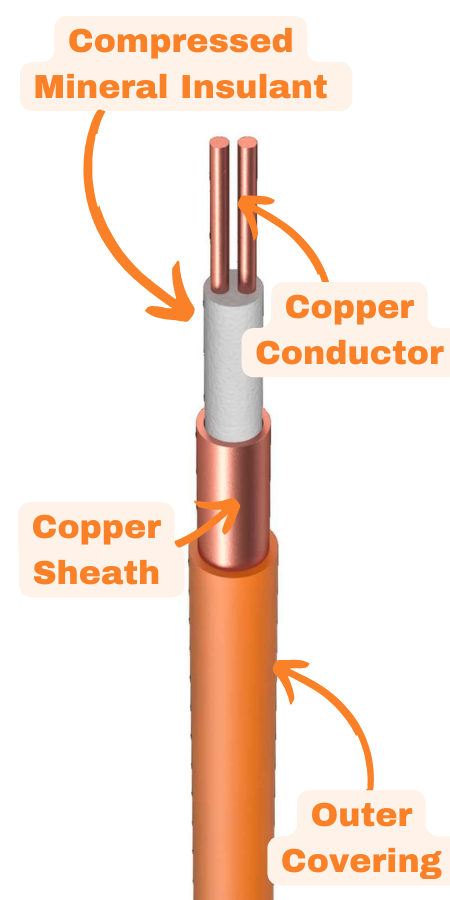

PYRO Cable

Also known as Pyrotenax cable is a type of fire-resistant cable typically used in buildings where fire safety is paramount. The main objective of this cable is to maintain circuit integrity even in the event of a fire, ensuring continued operation of main electrical systems when a fire alarm is activated.

Flex Cable

The name states its purpose, the flex is designed to be flexible without sustaining damage to the wiring.

It is commonly used in applications where frequent movement or bending is expected, such as in portable appliances, power tools, external routing, and machinery.

If you are interested in becoming a sponsor of the newsletter or want to be featured like Mark above please don't hesitate to reach out. Link to contact us below

Contact us here!The material and information contained in this newsletter is for informational purpose only, you should not rely upon the material or information on this newsletter, all readers must make their own judgment and seek professional advice when making decisions based on the context of the newsletter